Production planning and detailed planning

For more than 20 years, Opcenter APS has been the production planning software of choice for thousands of manufacturers worldwide. It is an essential step in achieving operational excellence. Their ability to be integrated into Manufacturing Execution Systems (MES), ERP (Enterprise Resource Planning) systems and the supply chain ensures a highly efficient manufacturing process. The result is great customer service and increased profitability.

With the following video you get a first exclusive insight into the functionality of the advanced planning solution Opcenter APS. Get to know its potential in less than 5 minutes.

Advanced Planning and Scheduling - Best Practices

In this Tech-Talk the following topics will be presented:

- References and practical examples from discrete manufacturing

- Considering multiple planning constraints: Detailed planning of machines with automated tool selection

- Mapping capacities: Influencing machining time by the resources used

- Optimize machine utilization: Taking job attributes into account to reduce setup times

Opcenter Planning

Planning can be performed in finite or infinite capacity mode, and the planning periods can be days, weeks, months, or a combination of all three. For each article code, parameters can be set that allow different calculations for each article. For example, some products may be in make-to-stock mode while others are in make-to-order mode.

When used in conjunction with an Opcenter scheduling system, detailed production plan information can be sent back to the planning system. The master production plan (MPS) can then be recalculated using the production plan as the basis for new results.

Opcenter Scheduling

The purpose of manufacturing planning is to minimize production time and costs by telling a manufacturing facility what to make and when, and what personnel and equipment to use. The detailed production planning is aimed at maximizing the efficiency of the operation and reducing costs. Detailed planning software is an important tool for many companies because it can have a major impact on the productivity of a process.

What is the difference between planning and scheduling / detailed planning?

The fundamental difference between planning and scheduling software is that planning systems are divided into so-called "buckets" (monthly, weekly, daily).

Scheduling systems do not have these "buckets", keep the order and can create work or dispatch lists. Assigning a task to a resource is a key function to achieve operational efficiency and optimize performance. Detailed planning uses a shorter time horizon and a much more detailed route than a planning system.

Advanced Planning and Scheduling - Best Practices

In this Tech-Talk the following topics will be presented:

- References and practical examples from the chemical, pharmaceutical and food&beverage industries.

- Manage resource capacities: live demo for tanks, ovens, cold storage cells, fast reaction to staff shortages or machine breakdowns

- Map job interdependencies: Group operations of multiple jobs into one batch

- Reduce cleaning times (CIP)

Individualization of your planning with Opcenter APS

Added value from Opcenter Planning:

- Decision support for long-term strategy

- Production load balancing and smoothing

- Fast creation of master production plans

- Fast response to changes in demand

Added value from Opcenter Scheduling:

- Better use of resources

- Reduced set-up and changeover times

- Reduced inventory levels

- Detailed visibility of production utilization

- Faster modeling of "what-if" scenariosImproved on-time delivery

-

MOM

Photo By: John DoeButton

We offer you support in the following areas:

- Finding solutions for your specific capacity planning and fine-tuning/detailed planning

- Implementation of your individual production planning with Opcenter APS

- Integration of Preactor into your (CLM) system landscape

- Project, sub-project management

- Implementation of Opcenter rollout projects

- GoLive and Post-GoLive Support

- Opcenter APS user training

Opcenter APS e-Book [EN]

Opcenter APS is a family of production planning and scheduling software products that improve the synchronization of your manufacturing processes, giving you greater visibility and control to increase utilization and on-time delivery, while reducing inventory levels and waste. Opcenter APS is a highly customizable capacity planning and scheduling package.

APS Flyer Wagner Informatik [DE]

Achieving Operational Excellence by relying on a digitalized and integrated planning and scheduling process through the entire manufacturing cycle. Lead the way to create and share sustainable value, to stay ahead of the curve.

APS Flyer Wagner Informatik [EN]

Achieving Operational Excellence by relying on a digitalized and integrated planning and scheduling process through the entire manufacturing cycle. Lead the way to create and share sustainable value, to stay ahead of the curve.

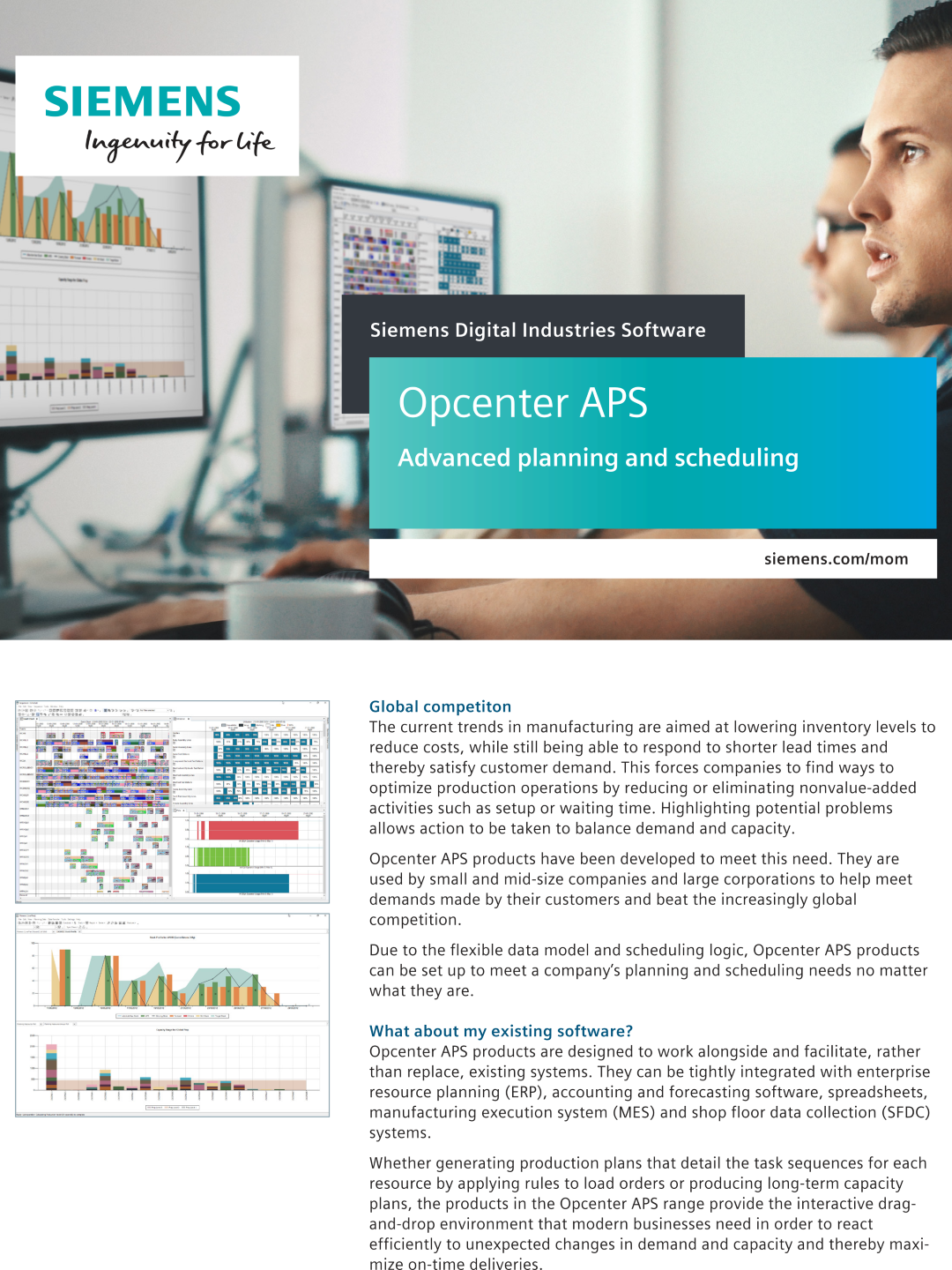

Opcenter APS Flyer - Advanced planning and scheduling [EN]

Opcenter APS is not a single point solution. It represents a family of prod ucts that, although based on the same core code, have different levels of functionality and pricing so that you can select the system that satisfies both your needs and budget. Upgrading to another product as your needs change is simple and easy.

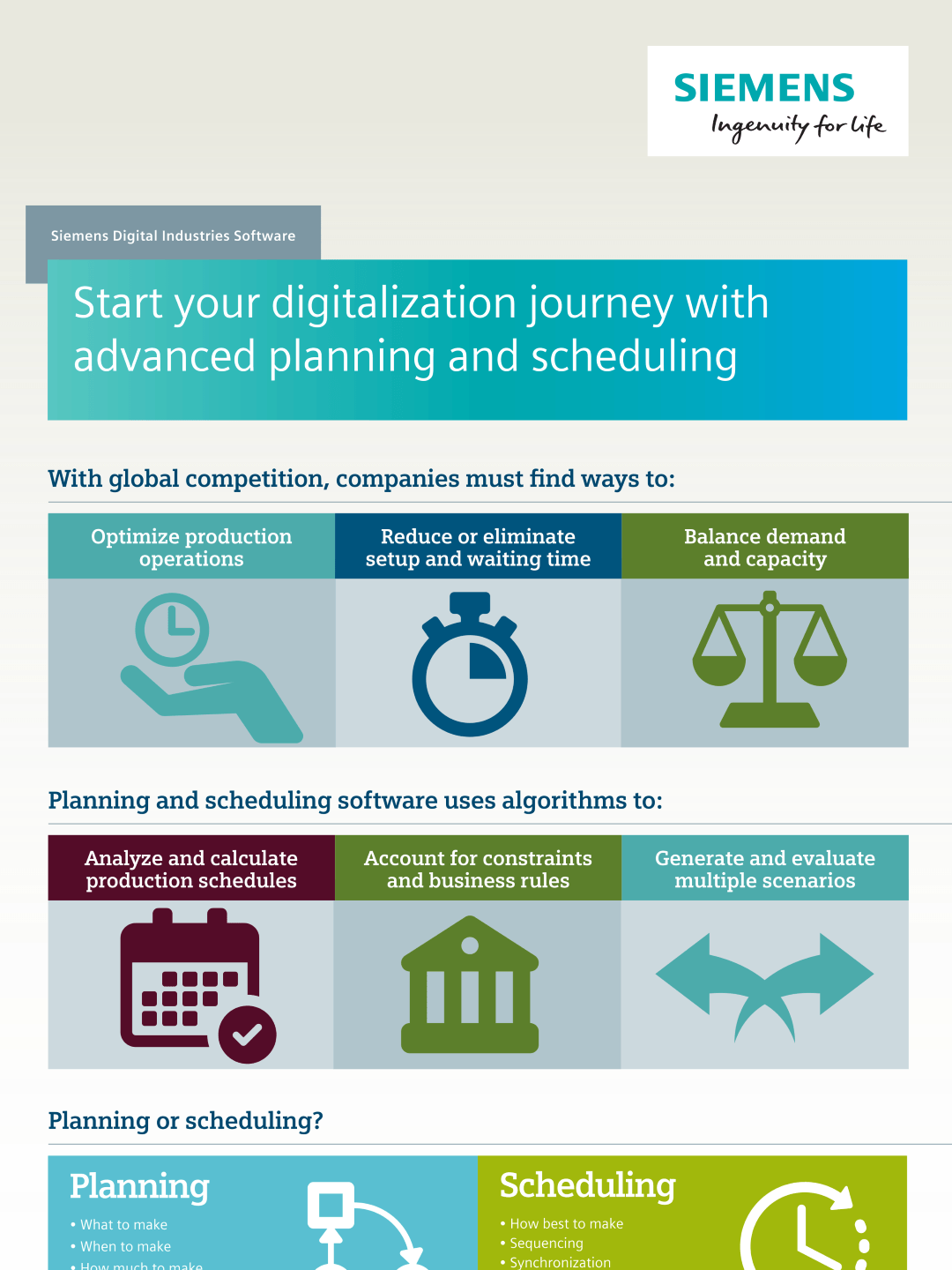

Start your digitalization journey with advanced planning and scheduling [EN]

Planning and scheduling solutions are suitable for any industry and for any size company from SMB to large enterprise.

Siemens SW Grupo Tigre Case Study [EN]

Opcenter APS enables Grupo Tigre to reduce inventory levels by nearly 50 percent.

Blog posts about #opcenteraps