Detailed production planning with Opcenter Scheduling

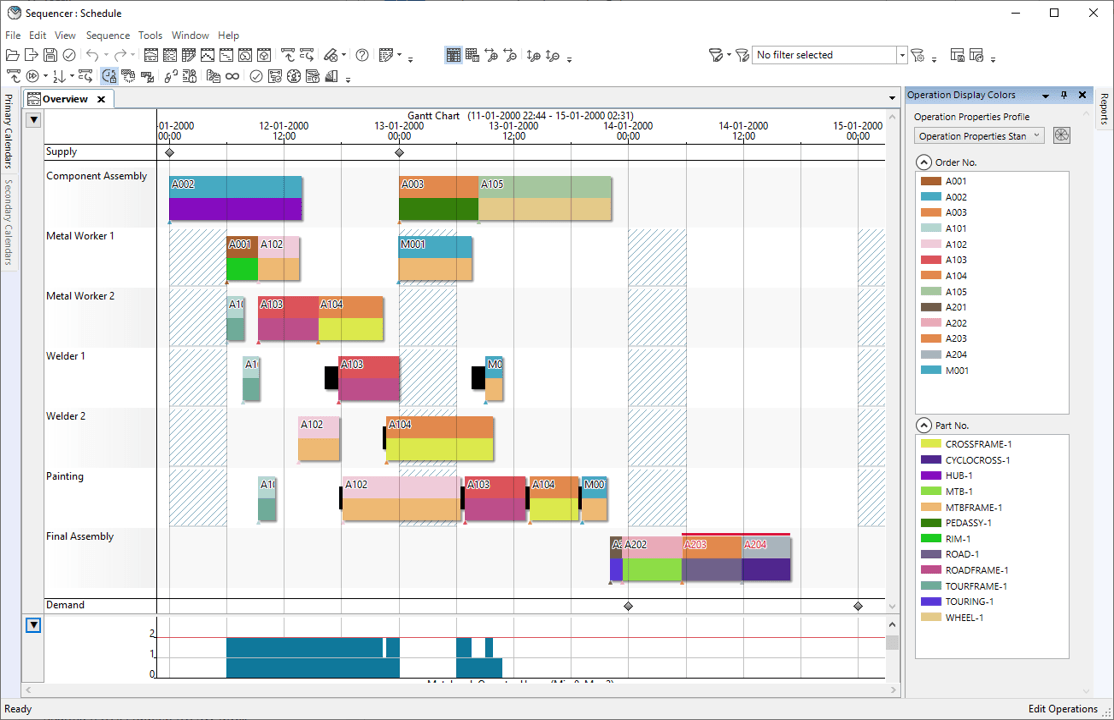

All products in the Opcenter Scheduling family are multi-constraint interactive scheduling systems. This means that resource availability and additional constraints such as tools and materials are taken into account during the planning process to ensure an accurate model of your environment. Jobs can be quickly scheduled using intelligent built-in rules, and the scheduler also has the ability to manually interact with the plan to make changes based on their experience or new information.

Opcenter Scheduling offers a whole new level of software customization, allowing the user to change the look and feel of the system directly. This includes a new data editor grid that allows the application of custom sorting, filtering and grouping, and selection of the fields displayed while viewing the data. There is also a powerful table and field editor tool that allows you to change the table and field names, redesign the dialogs and set the display attributes of the fields.

Detailed production planning with real use cases from injection molding production

The following topics will be discussed in this tech talk:

- References and practical examples from discrete manufacturing

- Consider multiple planning restrictions: Detailed planning of machines with automated tool selection

- Mapping of capacities: Influencing the processing time through the resources used

- Optimize machine utilization: Consideration of order attributes to reduce set-up times

Close integration with ERP and MES solutions enables rapid reaction to changes

- Best-in-class: Use of real-time production data for forecasting and synchronization

- These companies connect APS systems to their ERP, MES and shop floor data collection so they can monitor the status of execution versus plan.

Efficient use of resources in the chemical, pharmaceutical and food industries

The following topics will be discussed in this tech talk:

- References and practical examples from the chemical, pharmaceutical and food industries

- Manage resource capacities: Live demo for tanks, ovens, cold stores, quick reaction to staff shortages or machine failures

- Depict order interdependencies: Group operations of several orders in a batch

- Reduce cleaning times (CIP)

Opcenter Scheduling Standard:

- Opcenter Scheduling Standard has all of the features described above. It uses order-based scheduling to which the user can apply a ranking or weight to prioritize the orders. Scheduling is based on resource availability, additional constraints, and materials needed for the job.

- During the scheduling process, Opcenter Scheduling Standard can accommodate different task run speeds on different resources, use sequence-dependent switchover times based on task attributes, and allow for overlap and slack between tasks.

Opcenter Scheduling Professional:

- Opcenter Scheduling Professional has a number of additional schedule optimization rules to solve problems such as minimizing changeover times, preferential sequencing and campaigns. Composite rules can also be created using the Opcenter APS Workflow Tool. At the Opcenter Scheduling Professional level, the user can also implement customer-specific material consumption rules and visualize their assembly process from raw materials to finished goods and customer orders in the Material Explorer. This shows a graphical representation of the material dependencies as well as a graphical representation of stock levels over time.

- The user can see where bottlenecks will occur and decide whether to keep them as a constraint or ignore them. In addition, advanced resource constraints can be modeled with Opcenter Scheduling Professional, such as rules for the concurrent use of rules and advanced restrictions between the operations, such as restrictions on the time between operations and on extending operation times.

Opcenter Scheduling Ultimate:

- Opcenter Scheduling Ultimate includes a developer license (Opcenter APS Ultimate Access) that allows access to the full flexibility possible with an Opcenter APS system. The database schema can be modified as needed, including adding tables and fields, and through the Opcenter APS APIs it is possible to create custom rules to solve specific scheduling problems and create custom data manipulation tools for use with the Opcenter APS workflow engine.

- Because the Opcenter APS Ultimate Access license is a one-time purchase for an organization and is included in the price of the first Opcenter APS Ultimate system, this enables a cost-effective multi-licensing program for deploying Opcenter APS systems across multiple sites or planning environments.

Opcenter Scheduling Ultimate Viewers:

- The Opcenter Scheduling Ultimate Viewer is a system that can be connected to an Opcenter Scheduling Ultimate schedule. An Opcenter Scheduling Viewer system allows interaction with the schedule, but the changes cannot be saved. They can be used in the sales office to track the progress of orders and perform order queries against a read-only copy of the published schedule.

- Management can also use it to compare actual times to projected completion times to evaluate the performance of the production process. The viewers can also be used on a shop floor PC to provide the cell manager or machine operator with up-to-the-minute work lists generated by the planning system.

-

MOM

Photo By: John DoeButton

We offer you support in the areas of:

- Finding solutions for your specific capacity planning and fine-tuning/detailed planning

- Implementation of your individual production planning with Opcenter APS

- Integration of Preactor into your (CLM) system landscape

- Project, sub-project management

- Implementation of Opcenter rollout projects

- GoLive and Post-GoLive Support

- Opcenter APS user training

In addition to the detailed planning solution, also consider the rough planning with Opcenter Planning:

The variety of functions of the detailed planning solution:

Opcenter Scheduling Flyer Wagner Informatik [EN]

Opcenter Scheduling features a whole new level of software customization, putting the power to change the way the system looks directly into the user’s hands. This includes a new data editor grid that allows custom sorts, filters and groupings to be applied and enables the fields displayed to be selected while viewing the data.

Blog posts about #opcenteraps